All-terrain crane is a lifting equipment that installs the lifting system on a special wheeled chassis, and has the characteristics of both automobile cranes and off-road cranes. It is widely used in large-scale engineering projects such as wind power, petrochemicals, high-speed rail, nuclear power and mining.

1. In the late 1970s, the world's first all-terrain crane was developed and rolled off the production line in Germany, successfully opening up a new field for wheeled cranes.

2. my country's research on all-terrain cranes began in the 1980s. Due to the complex technology and multiple working conditions of all-terrain cranes and the blockade of related foreign technologies, the research and development work progressed slowly. In 2002, my country's first 25-ton all-terrain crane was born in XCMG, conquering the chassis suspension technology in one fell swoop.

3. It was not until 2010 that XCMG launched a 1,200-ton all-terrain crane, which not only broke the technical barriers of international giants, but also made China the third country in the world that can develop and mass-produce 1,000-ton full-terrain cranes. In the future, with the continuous advancement of technology and the continuous expansion of market demand, all-terrain cranes will play an important role in more fields.

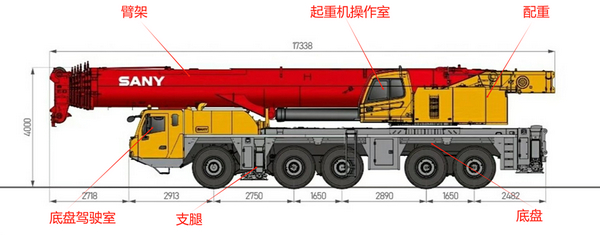

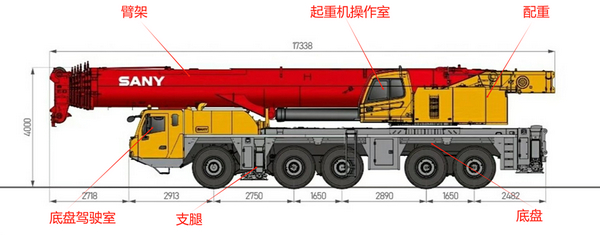

Schematic diagram of all-terrain crane

1. Hook: The lifting device of the crane.

2. Boom: A steel structure used to support the lifting wire rope and pulley block, usually made of high-strength steel.

3. Turntable: The slewing bearing is connected to the special seat ring of the chassis through high-strength bolts, and can achieve 360° rotation through the slewing mechanism.

4. Chassis: It adopts an off-road chassis with multi-axle drive and full-axle steering, as well as an oil-gas suspension system.

5. Outriggers: Most of them are H-shaped outriggers, while most large-tonnage all-terrain cranes use X-shaped swing outriggers.

6. Frame: It is mostly a multi-box thin shell structure welded from steel plates, with a complex structure.

7. Power system: Provides driving force for the crane.

8. Hydraulic system: Provides power transmission and control, used for the extension and retraction of the boom, the extension and retraction of the outriggers, and the operation of the slewing device.

Features

1. Good maneuverability: It provides three steering modes, including front-wheel steering, rear-wheel steering and all-wheel steering, so it has good maneuverability to adapt to different working environments.

2. Good stability: It is usually equipped with an oil-gas suspension system, which can provide better roll stiffness and longitudinal angular stiffness, so that it is more stable during lifting operations.

3. Strong off-road capability: It is usually equipped with multiple drive axles, providing good off-road capability and can operate on rugged or muddy sites.

4. Fast driving speed: It has the ability to transfer quickly, can travel quickly and long distances, and adapt to rapidly changing working environments.