As a leading enterprise in the road maintenance industry, XCMG has always been at the forefront of the times and is committed to providing a full range of road maintenance equipment and solutions; and has won wide recognition in the market with its outstanding technical strength and product quality. In addition to the core asphalt station products, the peripheral product configuration around the asphalt station is also very complete, covering emulsified asphalt equipment, flexible crushing equipment, warm mix foamed asphalt production equipment, production management system, cold addition system, insulation transport vehicle, etc., providing customers with one-stop professional services.

Through continuous technological research and development and innovation, XCMG has successfully developed a variety of advanced asphalt station supporting products to meet the ever-evolving market needs. After years of accumulation, XCMG has gained market recognition with its extraordinary achievements in the field of road maintenance equipment. These products complement each other with asphalt mixing stations, and together constitute XCMG's competitive advantage in the road maintenance industry, which can meet the various needs of customers in maintenance work. The advantages of these products are not only reflected in performance, but also help customers solve various maintenance problems, improve work efficiency and reduce operating costs.

XR series emulsified asphalt equipment is widely used in actual projects and can be constructed at room temperature. Compared with hot asphalt and diluted asphalt, emulsified asphalt can save 40%-50% of energy, which can help customers improve construction conditions, reduce project costs, and effectively reduce the problems of excessive aging of asphalt and large-scale volatilization of harmful substances caused by high-temperature heating. It is not only more green and environmentally friendly, but also can further improve construction safety.

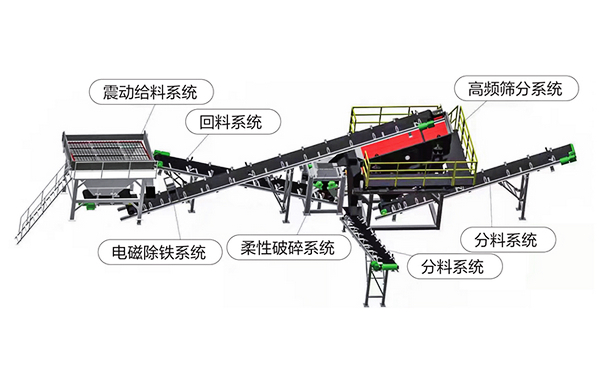

The flexible crushing equipment adopts a circular vibrating screen, the material running track is elliptical, the projection angle is close to a right angle, and the screening rate is greatly improved; the configured double-toothed roller crusher can achieve flexible crushing, so that the asphalt material is not damaged and the service life is longer.

The XFP series warm-mix foamed asphalt production equipment adopts warm-mix foamed asphalt technology and warm-mix recycling technology, which greatly increases the proportion of recycled material addition, reduces fuel consumption and harmful gas emissions, and truly realizes the green and environmental protection of asphalt mixing stations. And its "triple mixing" structure of the foaming tube can achieve efficient and high-quality foaming. The intelligent control system and precise metering system can ensure the accurate and intelligent addition of foaming water, making it more convenient to use.

As one of the star products in XCMG's maintenance industry, the XLY245B insulated transport vehicle has a very powerful performance. It solves users' construction problems with super insulation and efficient transportation, which is also the original intention of the birth of XCMG's insulated transport vehicle. It adopts a fully enclosed body, which can reduce temperature loss, effectively prevent segregation problems caused by temperature reduction, ensure that the asphalt mixture arrives at the front site with quality and quantity, and ensure the paving quality of the road. At the same time, the insulated transport vehicle adopts a scraper chain conveyor, with a reasonable rear overhang distance at the discharge port, and is equipped with a leakage prevention device, which can seamlessly connect various pavers to avoid contaminating the road surface.

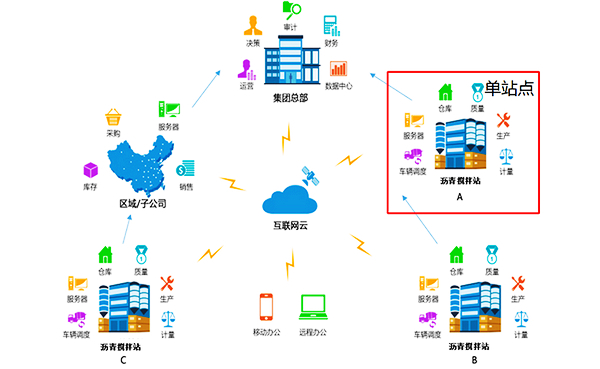

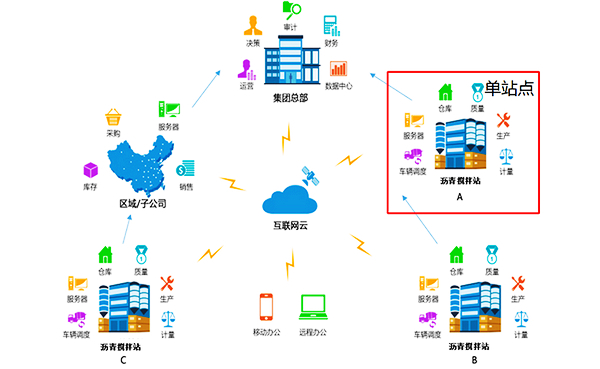

The operation of the asphalt station is also inseparable from the advanced production management system. XCMG's production management system integrates production planning, resource management, quality control, etc., to help enterprises achieve comprehensive monitoring and management of the production process. The full computer intelligent control technology can grasp the equipment status in real time; automatic temperature control, intelligent ventilation, convenient and fast operation; real-time monitoring of real data in all aspects of production and operation, effectively improving management efficiency.

XCMG's one-stop solution in the field of pavement maintenance keeps pace with industry trends and market demands, continuously conducts technological innovation and product upgrades, and ensures that it provides customers with more valuable services.